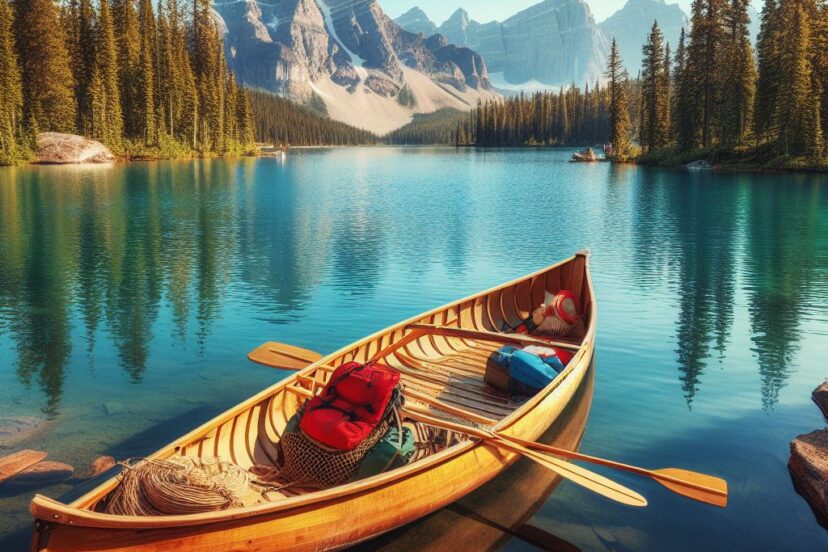

Wooden Canoe: Discover The Timeless Elegance

*We may earn a commission for purchases made using our links. Please see our disclosure to learn more.

Wooden Canoe: Craftsmanship, Techniques, and Traditions

Wooden canoes hold a special place in the hearts of paddlers and boat enthusiasts alike. There’s something truly unique about the craftsmanship and tradition that goes into each handcrafted vessel. Each wooden canoe is not just a mode of transport; it’s a piece of art, a nod to history, and a symbol of dedication to quality.

I’ve found that the beauty of wooden canoes isn’t just in their look but also in their performance. They offer a smoother, quieter ride compared to their modern counterparts. Builders like Northwoods Canoe Company and Bear Mountain Boats continue to keep this heritage alive with their well-crafted models and detailed building kits, providing enthusiasts with the opportunity to either buy or create their own.

From the sturdy, customizable designs offered by Merrimack Canoes to the educational resources provided by the Wooden Canoe Heritage Association, the world of wooden canoes is rich with options and history. Whether you’re a seasoned paddler or a curious beginner, exploring wooden canoes can open up a new appreciation for the past and the art of boat building.

History of Wooden Canoes

Wooden canoes have a rich and fascinating history, starting with indigenous designs, evolving through periods of trade and development, and seeing a revival in modern times.

Indigenous Origins

Native American tribes were the first to craft wooden canoes. They used bark, typically birch, to create lightweight and efficient vessels. These early canoes had a simple, yet highly functional design. They were crucial for hunting, fishing, and transportation across rivers and lakes.

Indigenous people perfected their building techniques over centuries. They knew how to select the best trees and used heat to shape the wood. The canoes varied in size, some large enough to hold several people and their gear.

Early wooden canoes were a product of necessity and ingenuity. They were built by hand, using tools made from stone and bone. The craftsmanship involved made each canoe unique, reflecting the skills and resources of its maker.

Development and Trade

In the late 19th century, companies like the Chestnut Canoe Company and Old Town Canoe Company began producing wooden canoes commercially. These companies improved on the indigenous designs, using canvas-covered wooden frames.

Canvas canoes offered durability and ease of repair. They became popular among outdoor enthusiasts and explorers. These canoes were lighter and easier to handle than those made entirely of wood, making them ideal for long trips.

By the early 20th century, wooden canoes were a common sight. Their popularity grew as recreational paddling became more widespread. Companies developed various models to suit different needs, from racing to leisurely paddling.

Modern Revival

Despite the rise of synthetic materials, wooden canoes have seen a revival. Enthusiasts still value their beauty and craftsmanship. Organizations like the Wooden Canoe Heritage Association work to preserve the tradition and educate the public about these vessels.

Artisans today continue to build wooden canoes using traditional methods. Some modern builders blend old techniques with new materials to enhance performance.

These canoes are now prized collectibles and functional works of art. They symbolize a connection to the past and a commitment to preserving a beautiful craft.

Types of Wooden Canoes

There are several distinct types of wooden canoes, each with unique features and history. Here are the most common types: Birchbark canoes, cedar strip canoes, and dugout canoes.

Birchbark Canoes

Birchbark canoes are traditional canoes made using the bark of birch trees. These canoes were originally crafted by Native American tribes. The bark is sewn together with roots and sealed with sap to make the boat watertight.

Birchbark canoes are lightweight, allowing for easy portage and efficient travel across both rivers and lakes. They often feature a unique, natural aesthetic that reflects their hand-crafted origins.

Despite their delicate appearance, these canoes are quite durable. Their construction materials allow them to flex slightly, absorbing impacts from rocks or other obstacles in the water. This flexibility makes birchbark canoes excellent for navigating shallow or rough waters.

Cedar Strip Canoes

Cedar strip canoes are a popular choice for their combination of beauty and performance. Made by gluing thin strips of cedar together, these canoes are lightweight and strong. The wood is sealed with fiberglass and resin to make them waterproof.

Cedar strip canoes often have sleek, smooth designs. The wood’s natural grain gives the canoe a striking appearance, which many paddlers find appealing. These canoes are ideal for flatwater paddling, as they glide smoothly and handle well.

Crafting a cedar strip canoe can be a rewarding project. While they can be purchased pre-built, many enthusiasts enjoy building their own from kits. This allows for customization in terms of length, design, and finish. Pre-built cedarstrip canoes start at $2,000, and cedar canvas canoes start at $3,000. Wooden canoe kits cost a little less, starting closer to $1,500.

Dugout Canoes

Dugout canoes are one of the oldest types of canoes. They are made by hollowing out a single large log, usually from a tree like cedar or oak. These canoes were used by many ancient cultures around the world due to their simplicity and durability.

Unlike other wooden canoes, dugout canoes are heavier. This can make them less convenient for portaging but gives them excellent stability in the water. Their solid, sturdy construction allows them to withstand rough conditions and heavy loads.

Crafting a dugout canoe requires significant skill and time. The process involves careful carving and shaping, often using traditional tools. The result is a canoe with a deep cultural significance and a unique, timeless design. Dugout canoes provide a tangible connection to history and craftsmanship that modern canoes may lack.

Construction Techniques

In this section, I will cover the methods used in building wooden canoes, focusing on traditional techniques and modern practices.

Traditional Methods

Traditional canoe-building methods often involve using natural materials and craftsmanship passed down through generations. The cedar-strip technique is popular, where narrow wooden strips are glued together with carpenter’s glue to form the hull. Each strip must be carefully aligned to ensure the canoe’s shape and strength.

Another method is the wood-and-canvas canoe, rooted in the birchbark canoes of the First Nations people. This involves stretching canvas over a wooden frame and covering it with a waterproofing solution. The frame typically includes the keel and ribs, which are the backbone and ribs of the canoe, respectively.

Contemporary Tools and Practices

Modern canoe construction often integrates power tools and advanced materials for efficiency and durability. Tools like band saws and orbital sanders help shape and smooth the wooden strips quickly. For adhesion, epoxy resin is now commonly used instead of traditional glues, as it provides stronger and more flexible bonds.

Fiberglass cloth is often used to cover the wooden hull. This not only adds strength but also makes the canoe more resistant to water and impact. Builders also use precise molds and jigs to ensure uniformity and streamline the building process.

These contemporary tools and practices enhance both the durability and ease of building wooden canoes, combining traditional aesthetics with modern performance standards.

Maintenance and Preservation of a Wooden Canoe

Maintaining a wooden canoe involves regular cleaning and timely repairs. Keeping the canoe clean and sealing scratches help preserve its condition.

Regular Upkeep for a Wooden Canoe

I keep my wooden canoe in good condition by removing mud and sand after each use. This prevents grit from wearing away the finish. I also check for scratches and seal them immediately to prevent more damage.

Cleaning is straightforward. First, I rinse off dirt with fresh water. Then, I dry it thoroughly to avoid moisture damage. Occasionally, I use a fine abrasive to smooth out any rough spots, ensuring the wood looks pristine.

Periodic checks: I inspect the varnish and reapply it as needed. The varnish protects the wood from moisture and sun. Pay attention to high-abrasion areas like the floor. If the varnish wears off, moisture can damage the wood underneath.

Wooden Canoe Use and Handling

Using and handling a wooden canoe involves understanding both paddling skills and maintenance practices. Keeping these canoes in excellent condition ensures a great experience on the water.

Paddling Skills

Paddling a wooden canoe requires some practice and technique. To start, getting familiar with the basic strokes is essential. The forward stroke, J-stroke, and sweep stroke are key moves.

I always recommend sitting or kneeling in a way that balances the canoe. This provides better control and stability.

Choose the right paddle: Typically, a wooden paddle complements the feel of a wooden canoe.

Practicing in calm water is best for beginners. It allows you to focus on your strokes without strong currents. Remember, consistent practice builds confidence and skill.

Frequently Asked Questions

When it comes to wooden canoes, many ask about their construction, maintenance, and key features. Here, I’ll address these common queries for you.

What are the disadvantages of owning a wooden canoe?

Wooden canoes require more maintenance than synthetic ones. They’re also prone to damage from moisture if not regularly treated. Additionally, wooden canoes can be heavier, making transportation tougher.

How are wooden canoes constructed?

Wooden canoes are often built using a wood-cored composite structure. Builders start by shaping a wooden frame and then covering it with layers of fiberglass or canvas. This process ensures durability and aesthetics.

What maintenance is required for a wooden canoe?

Regular maintenance is crucial. You need to sand and varnish the wood to protect it from water damage. It’s also important to check for and repair any cracks or breaks in the wood or fiberglass.

What factors should be considered when purchasing a used wooden canoe?

Look for signs of water damage, such as rot or mildew. Check if the canoe has been well-maintained with regular varnishing. Ensure the structure is sound, with no visible cracks or weak spots.

How does the weight of a wooden canoe compare to canoes made from other materials?

Wooden canoes are generally heavier than canoes made from materials like aluminum or fiberglass. This extra weight can make them sturdier but also harder to carry and transport.

What are the key features to look for in handmade wooden canoe designs?

Focus on craftsmanship and quality of materials. Attention to detail in the joinery and finish is crucial. A well-designed wooden canoe should have balanced proportions and smooth lines for better performance on the water.